LivaNova understands its responsibility to protect the environment and minimize the Company’s environmental impact throughout the operating cycle. In its manufacturing and operations, the Company is working to optimize energy and resource usage to ultimately reduce greenhouse gas emissions and waste. Among other things, the Company’s sustainability efforts are informed by Sustainability Task Force member work within the organization, regulatory requirements, customer needs, and AdvaMed, MedTech Europe, and the United Kingdom (UK) National Health Service (NHS) engagement.

Planet

Environmental Sustainability

Environmental Sustainability

Achieving Net Zero Carbon Emissions

In line with LivaNova’s sustainability strategy, the Company is committed to achieving net zero carbon emissions by 2050 and improving resilience in a changing climate. Accordingly, LivaNova has adopted the following near-term, global targets:

- Scope 1 and Scope 2: 54.6% reduction by 2033 from a 2022 baseline year, based on the limiting warming to 1.5°C aligned pathway; and

- Scope 3: 27.5% reduction by 2033 from a 2022 baseline year, based on the limiting global warming to well-below 2°C aligned pathway.

LivaNova’s target setting method is based on the absolute contraction approach of science-based target setting and progress against these targets is incorporated within the Company’s Carbon Reduction Plan and UK Annual Report, both of which are located on the Company’s website.

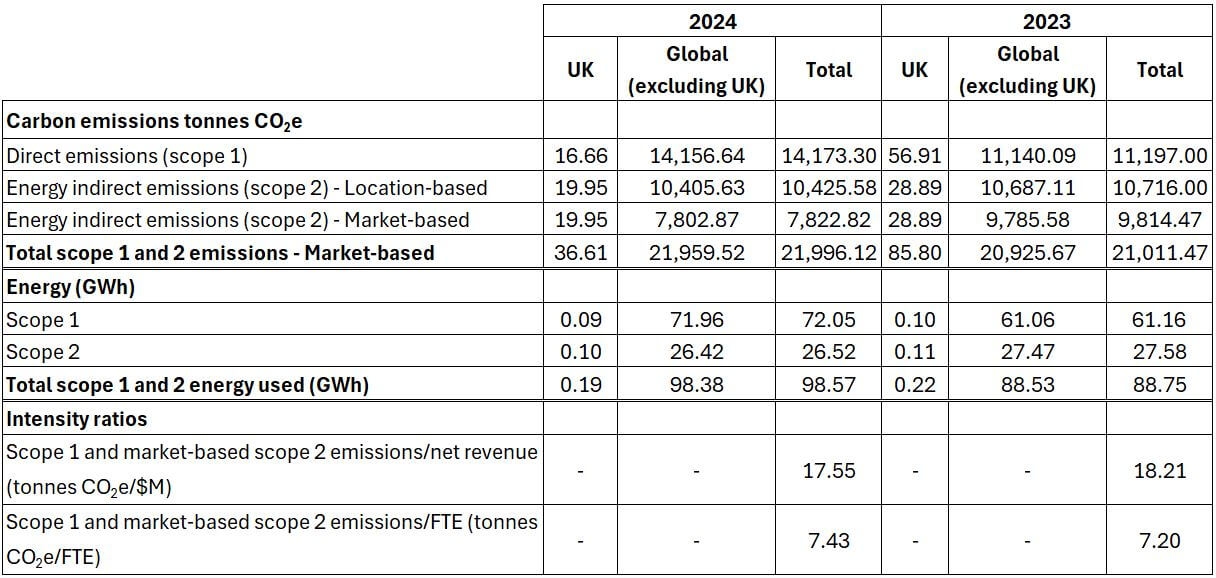

While the majority of manufacturing sites increased output to support increased net revenue of approximately 8.7% in 2024 as compared to 2023, the tonnes CO2e per net revenue (US$M) decreased by 3.6%

What We Are Doing

Climate

Initiatives

Packaging and Product End of Life Optimizations

Climate Initiatives

In its manufacturing and operations, LivaNova is working to optimize energy and resource usage to reduce greenhouse gas emissions and waste.

2024 progress towards achieving LivaNova’s Net Zero targets included:

- Updating electricity contracts to require the use of certified 100% renewable energy for the Gloucester office and the Houston, Melbourne, Mirandola, and Munich facilities (4 of 6 global manufacturing sites);

- Establishing a Zero Waste to Landfill* 2030 target for LivaNova’s manufacturing sites to increase recycling, with:

- Mirandola achieving 91% Zero Waste to Landfill,

- Munich achieving 67% Zero Waste to Landfill, and

- Continuing the certified Zero Waste to Landfill status since December 2017 in the Gloucester, UK operational office;

- Continuing use of digital business cards to reduce paper usage and waste;

- Continuing to add hybrid vehicles to the European fleet; and

- Installing EV charging stations at multiple sites, supporting those employees and visitors who want to commute using electric vehicles.

* Waste disposal with Recycle destination (tons) ÷ Total waste (hazardous and not hazardous) (tons)

Packaging and Product End of Life Optimizations

In furtherance of LivaNova’s decarbonization efforts, the Company is working to optimize packaging design, aiming to use the least amount of material, while ensuring adequate protection, delivery, and safe use of the product, as patient safety is paramount. LivaNova’s materials management is guided by the waste management hierarchy seeking first to reduce, reuse, and recycle (e.g., 3R). To achieve increased certified recycled content and reduced packaging waste, LivaNova has developed a global 3R Packaging Plan with initiatives embedded into the Company’s strategic plans.LivaNova’s product packaging indicates recyclability via affixed label and/ or symbol. The packaging may be recycled in accordance with local recycling regulations.

Currently, certain LivaNova product packaging includes certified recycled content. Specifically:

- Suppliers of external fiber-based packaging for products are Forward Stewardship Council® (FSC), Program for the Endorsement of Forest Certification® (PEFC), or Sustainable Forestry Initiative® (SFI) certified and provide certified packaging products to LivaNova;

- Sterile standalone versions of InspireTM oxygenator and reservoirs are packaged using certified 100% recycled paper pulp;

- Supplier of external packaging for InspireTM perfusion tubing system (PTS) sterile standalone products is certified as Ecovadis Silver level1;

- Other product families (including Custom Packs and XTRATM Autotransfusion System) have external packaging of recycled fibers with certified recycled content ranging between 45% and >90%;

- EssenzTM Perfusion System is packaged using carton boxes with certified at least 58% recycled material; and

- S5TM Heart Lung Machine (HLM), XtraTM Autotransfusion System, and Xvac are packaged using carton boxes with minimum 80% recycled material.

Other Sustainability Focus Areas

Corporate Governance

Our Board of Directors and executive leadership team ensure accountability, transparency, and fairness throughout the company. Governance practices influence our corporate strategy, business operations, environmental impacts, ethics & integrity, compensation, and management of risk. The Board continually considers corporate governance improvements and models a culture of compliance.